Radio W4KAZ Thanks for stopping by the virtual KazShack. Feel free to comment - I often approve them.

|

By w4kaz, created on 2012.06.01 at 06:39:54 | last changed on 2013.06.10 at 08:31:17 | Tribander Plus? Plus what? Friends with benefits maybe?

Back in 2002 or so, references to the “open sleeve dipole” sparked a curiosity in the topic. Very few web references were available back then(in the internet dark ages). The article that initially tweaked the curiosity was N6LF’s article “A Wideband 80-m Dipole”, which built upon an earlier article by K9AY from 1995. The open sleeve idea is also mentioned by Bill Orr, W6SAI. Current ARRL Antenna books have information on this topic in Chapter 10, but that was not available in 2002. Not much else, but there are a few engineering references going back at least as far as 1945. None of which were readily available a decade ago. Time marches…..

Recently Joel Hallas, W1ZR, ran a couple of articles on the subject in QST. This article on adding 6m to a tribander duplicated an idea I had myself, although I was more interested in the possibility of easily adding 17m to a tribander. W1ZR uses the term favored by K9AY, the “coupled-resonator”, from K9AY’s article “The Coupled-Resonator Principle: A Flexible Method for Multiband Antennas†in the ARRL Antenna Compendium #5. K9AY’s “coupled-resonator” terminology is more precise and accurate as a general description of the principle for amateur uses. Yet my own fuzzy gray matter remains wed to the term “open-sleeve”, which is really an example of the general principle in a narrow usage.

More references are available today: NQ6K with a well written treatment used as a sloper, and DK7ZB has a good page briefly explaining the concept. Plus a new ARRL Antenna book(Chapter 10.4-10.5) entry. This is the idea in general terms. Placing another wire in parallel and “close” to another dipole allows you to feed the antenna at two different resonant frequencies. The feedline is attached to the longer dipole only, the second(and/or third) wires are excited parasitically. By carefully spacing the two wires, it is possible to get a 50 ohm match for both resonances.

Pretty handy idea….but….

O’course, the trick is in the details. Getting the spacing correct can be tricky if you are intent on that 50 ohm match. EZNEC modeling is simple enough for this gray cat, and it is easy enough to fiddle the dimensions of the second dipole and its length to get that 50 ohm match. It turns out you can also add a third dipole too, but the spacing dimensions become a lot more critical. Much like a fan dipole.

Generally, it seems that the higher frequency dipole winds up being slightly shorter than it would if it were a single dipole, and that is more pronounced as additional resonators are added. Harmonic combinations also seem more sensitive to dimension changes affecting feed point impedance. [NOTE: ARRL antenna book, chapter 10.5 contradicts my note of “slightly shorter”, indicating the dipoles might need to be slightly LONGER due to the capacitive coupling. Hmmmmmmm. Mayhaps wire spacing….?]

Outside the box of conventional

But what if we do NOT concentrate on the 50ohm match? What if we wish to use a balanced line feeder and a tuner, like for, oh, maybe a multi-band wire antenna for FIELD DAY? Something with improved and predictable radiation patterns over a non-resonant doublet?

That seems to be a pretty good option. The dipoles are resonant, even if they show an impedance that is not 50 ohms. Resonance does not imply 50 ohms….that is just a happy convenient choice since radios are designed to have input impedances coincidental with the general impedance of a half-wave dipole fed in the center. But an end fed half wave is just as resonant even though the impedance is nowhere near 50ohms.

With resonance the radiation patterns are more predictable, and there are less likely to be odd lobes as might be the case with a generic doublet. In the past we have used several different options for loading up a doublet on multiple bands, with mixed results. So in April I decided to cobble an open sleeve antenna together and try it out for a few days.

Models? We don’ neeed no steeeenkeeeng models…

No, but in this case the model was interesting. Going for a decent compromise of performance versus convenience, a bit of EZNEC tinkering showed that a 40m/20m/10m combination of elements might produce decent radiation pattern results for four bands. Input impedance? Maybe not so ideal.

The plan modeled was using 18ga ladderline for the mid-section, and attach legs on the ends for the 40m resonator. Spacing the 10m wire at about 1.5 inches in the model produced a more stable impedance curve for 10m, so rather than just taping the 10m wire to the ladderline, small spacers are used. Radiation patterns for 40m and 20m resemble normal dipole patterns. The 15m pattern is normal for a 40m wire pressed into 15m service – a dipole pattern that is breaking into two lobes with a nulled lobe perpendicular to the dipole. The 10m pattern without the 10m element would show the same butterfly pattern. Adding the 10m element makes a huge difference on both the radiation pattern and the feedpoint impedance in this instance.

Actual antenna

The antenna was constructed from a segment of 18ga 450 ohm ladder line and some scraps for 14ga thhn laying about. The ladder line section was from a 20m folded dipole. The parasitic radiators modeled best if the were slightly shorter than they would be in a single wire dipole. So the ladderline was shortened to the model’s 20m dimensions. Enough wire to complete the 40m legs to model dimensions was added to the fed wire. Dimensions were pulled directly from the model for all legs – no other trimming, and the pieces stitched together. [No point in trimming since the intent is to feed the antenna with ladder line to a tuner, rather than obtain a 50 ohm match directly.] The 10m radiator was attached to the ladder line via a few sections of PVC pipe cut into 2 inch lengths for use as spacers. These spacers were drilled and attached to the ladderline via cable ties and tape. The 10m element then is attached to the outside of the spacers, away from the ladderline.

In hindsight, adding the 10m element with spacers is problematic for a “portable” antenna. The spacers complicate storing and deploying the antenna.  Just taping the 10m element to the ladderline is probably worth the efficiency trade off – unless you have real reason to expect 10m to be significantly better than it has been of late.

The end result is a dipole that exhibits the radiation pattern of resonant dipoles on those three bands, and also is relatively easy to load on 15m. The model show the 15m pattern is “butterfly” shaped, which is normal for a 40m dipole pressed into service on 15m.

Workee workee

It is now hung at almost exactly 30 feet height, and shows the expected performance on those four bands. One of the major lobes on 15m must be favoring Europe, as the EU stations are better on this antenna than anything else in the yard. 20m and 40m are equivalent to the other dipoles. Not much 10m activity heard yet, so no idea there.

I expect a similar fan dipole could be used in the same manner, where all of the dipoles are physically attached. My experiments with fan dipoles was in an attempt to match to 50 ohms. Very difficult to do for more than 2 bands.

Another caveat to be aware of is that combinations of dipoles at widely separated frequencies, i.e., more than a harmonic, will tend to have “unusual” patterns.

There were too many outside issues to allow much butt-in-chair time in one of my favorite contests, CQ WPX CW. But enough of a chance to try the antenna out, and I’ happy with the results. The butterfly lobes on 15m must be in very favorable directions. During the contest Europeans had huge signals, and I worked three JA stations on Sunday afternoon….which are certainly the only JA’s worked from this QTH this decade.

I’ll not leave it up permanently, because running the ladder line into the shack always raises RFI issues. This antenna is RFI “cranky” on both 40m and 15m inside the shack, but thats probably more an issue related to the kludged feed-thru into shack and the general in-shack rat’s nest of wiring rather than the antenna. It is worth testing out for a bit longer though.

Maybe a few RFI issues will find resolutions during the testing.

Interesting open sleeve(coupled resonator!) ideas….

NQ6KÂ slopers…. http://findatlantis.com/wiki/index.php/20-15-10m_Triband_Sloper

N6LF Wideband 80m dipole:Â http://rudys.typepad.com/ant/files/antenna_broadband_dipole.pdf

Dan Levin, N6BZA and Marty Levin, W6BDN: Notes on phase delays when stacking: http://www.k6if.com/c3_stack_article.html

By w4kaz, created on 2012.05.31 at 05:30:50 | last changed on 2012.05.31 at 09:00:10 | “Don’t get cocky kid….”

Just when everything seems to be going smoothly, Murphy arrives. Two days before the WPX contest, it became clear the 80m softrock had developed an issue and was useless. It lost half of the signal, and so was useless(on 5/27) and required repairs. Sideline that issue for now….

The 40m skimmer session kept right on chugging. A couple of problems became clear.

- The softrock will need better band pass filtering if they remain active during operations, or switching to shut them down during transmit

- running CW skimmer at 192khz sample rate used a great deal of CPU time, averaged 45-50% CPU utilization.

- Limiting the number of decoders helped somewhat

- Reducing the scan rate to allow a 96Khz bandwidth drastically reduced the CPU usage. Running at 96khz required an average of 15-20% of the CPU, even with the limit on the number of decoders increased.

- The K9AY rx antenna worked well for the 40m SR skimmer. The problem is it will need to be split and amplified for 80m and 160m as well.

All together, it looks like the skimmer posted about 8K spots while it was active during WPX. Trying to figure out a way to check for errors. Low priority – spot checking the spots showed most to be valid.

The 80m SR problem was resolved on Monday evening. After having made three passes over the op-amp section, I made a fourth pass, concentrating on components in the “ring” side of the op-amp output, as well as the path back to the QSD section. Also made a first pass over the transformer solder joints, using a higher wattage iron. 80m issue resolved. Odds are it was in the op-amp chain(seems to be the most common cause of the symptoms), but I suspect a cold solder on the transformer was the real culprit.

Looking at the case from a dead home audio system as a permanent enclosure. If I can fit everything in, it should be a good choice. Time for a block diagram…

By w4kaz, created on 2012.05.22 at 09:07:00 | last changed on 2012.06.13 at 23:06:46 | Note….Post dated this material to original date written…superseded by new reality…..

“All is proceeding as I have foreseen it…………..”

Been just about four years since the CW skimmer stuff really hit the contest rotary impeller. A bit of review…..

So in hindsight – I’m glad contest sponsors read my blog. 😉

Since the rule-parsing panned out to my immense satisfaction, it is easier to concentrate on the toy itself. Since then, skimmer stations sprouted, and the Reverse Beacon Network was born. That is a really interesting project. Its a great tool for checking propagation, comparing station signals, and getting impartial signal reports. Outstanding resource.

Unfortunately there is not a local skimmer station that is feeding the RBN. Spots from MD are not always useful in Central NC.

So it with the moon in phase and the planets approaching the grand alignment, it seemed like time to look into the subject of skimming.

Options

The Skimmer software comes with a component that is designed to work with the QS1R SDR. That combination is likely the ideal solution. So all I need is a fast Pentium i7 Quad core, and a thousand samolies…… Great idea, just not possible.

Much more possible….Combine a few Softrocks with some cast off circa 2008 computers. Yup, that’s the ticket. Rather than sit on my thumbs….Engineer the Possible. O’course, the possible is not always completely practical. Everything is relative. What tradeoffs are reasonable? Engineer the Possible.

It has been done before…AC0C has documented the challenges and his solutions. Despite the validity of his conclusions, it is now possible to cobble together a scaled down version using scrounged computer hardware. Using softrocks, it is now very practical to put together a skimmer package for 160/80/40/20 meter bands with obsolescent computer hardware.  The price/performance ratio of the softrock is a huge factor. If they were a mass production commodity, they would probably cost under $10.

15m and 10m may be more of a challenge, so that has been shelved for the moment. So the softrock solution is not perfect. But there are solutions to that too. Future project….

The current project direction

So the game plan is to skim on 160m thru 20m using softrocks. 40m and 80m softrocks are done. Its not going to be as professional a finished product as AC0C’s, but it should function. Reclaimed from the off-lease refuse stream are an Dell Optiplex 745sff and a Dell optiplex 360 SDT. Both of these boxes require low-form-factor cards. The on-board sound of the 745 leaves something to be desired, but the 360 has an on-board sound card capable of 192khz bandwidth. So small form factor add-in cards are needed to run skimmer on multiple bands. Four bands on two computers.

Other Naughty Tidbits….

The Asus Xonar DG is a small form factor sound card that turned out to be a fabulous bargain. It allows only 96khz bandwidth, but has excellent dynamic range for its cost. Sounds great with music too. Also had an Asus Xonar DX, which is higher fidelity than the Xonar Dg, and offers 192khz bandwidth with a softrock. The sound card issue is the real sticking point in this design, but the Xonar cards are able to coexist with the onboard SoundMax devices in the Dell boxes.

Not so much luck with a Soundblaster Live 24. Experiments installing and using the Soundblaster were problematic. Compatibility issues with the other sound devices and SDR software crashes. The Asus cards are much higher quality, but attempts to pair either with the soundblaster caused problems. Attempts to install both Xonar cards in the same system were also buggy. So the Soundblaster is sidelined for later rainy day experimentation, the ASUS cards are each on a different host system, and it is fortunate that the onboard sound cards are useable.

The final compromise chosen was to install the 192khz Xonar DX in the Optiplex 745 that has 48khz onboard SoundMax. The Xonar DG is installed in the Optiplex 360 that has 192khz SoundMax onboard sound. In testing the Xonar cards work very well with all of the SDR software tested. The SoundMax cards are noticeably less capable, but not terrible.

Mix and Match

The skimmer sessions sound card pairings in daily usage are likely to be:

- 160m…48khz on Optiplex 745 onboard sound

- ……………..Center@????????,Covers ?

- 80m…..96khz on Optiplex 360 Asus Xonar DG

- …………….Center@3533950, covers ~3485 thru 3581

- 40m…..192 or 96khz on Optiplex 745Â Asus Xonar DX

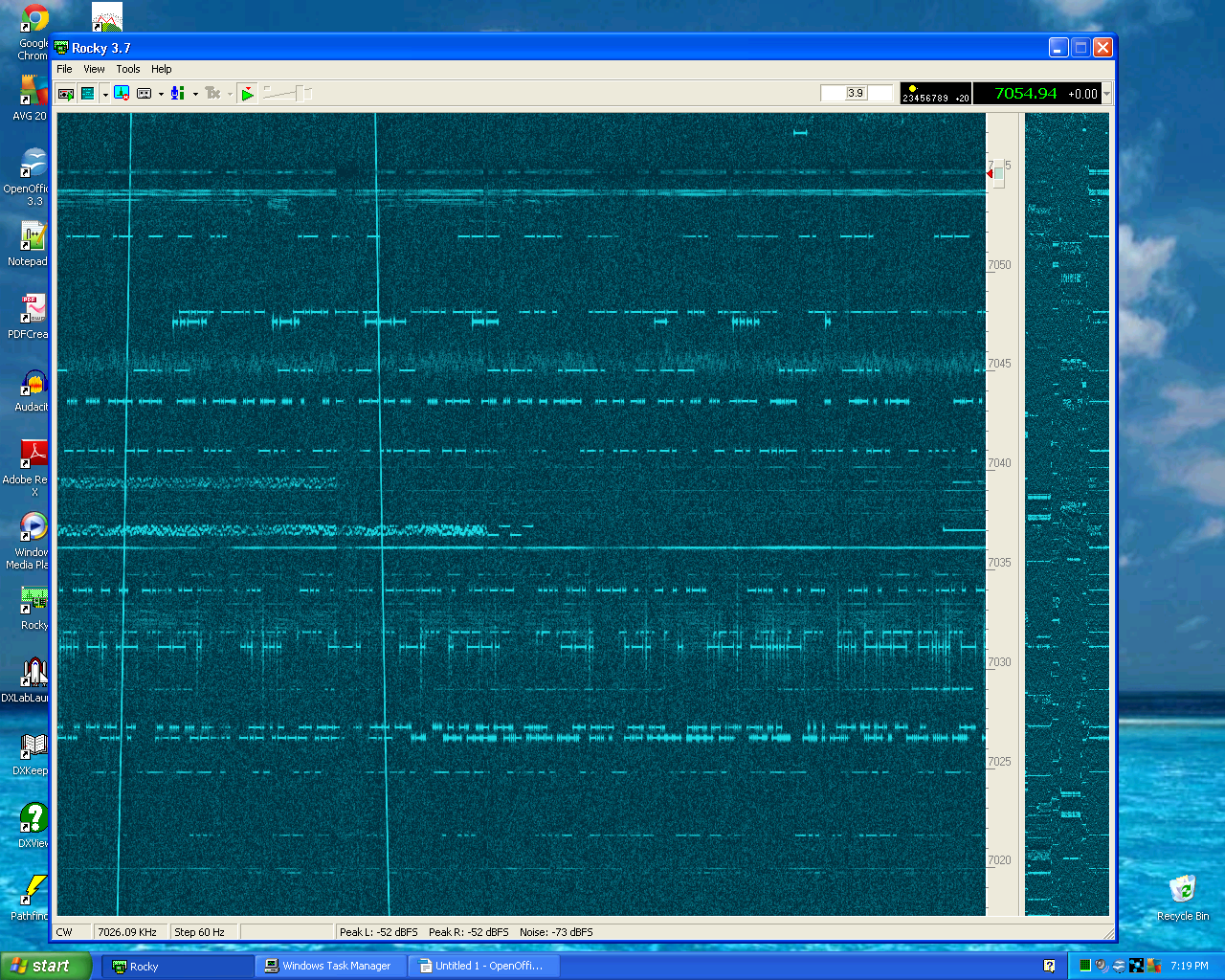

- …………….Center@7055015, covers ~6959 thru 7151@192Khz, 7007 thru 7103@96Khz

- 20m…..192 or 96 Khz on Optiplex 360 onboard sound

- ……………..Center@????????,Covers ?

Those pairings should spread the CPU load somewhat. A live test on 40m and 80m during CQ WPX should give me a benchmark for CPU loading. CW Skimmer allows the definition of the maximum number of active decoders, and I expect to get some insight on setting those values to help moderate the load. Currently, allowing 500-600 decoders seems workable.

During 160m contests, the 160m skimmer will likely switch to a wider bandwidth card, at least 96Khz. The fall contest season will allow more testing to determine if the 192khz skimmers will need to be narrowed during contests or throttled by limiting the max number of decoders – maybe both. Also, the nature of any given contest may also make temporary changes to the line-up appropriate. But that’s the basic setup.

Using the spots

The Reverse Beacon Network Blog has info on connecting to the RBN telnet server. Highly recommend taking their advice on filtering!  The RBN server uses DXSpider documented on DXSpider Wiki.

By w4kaz, created on 2012.05.22 at 06:32:18 | last changed on 2012.05.21 at 22:32:36 | After some large amount of initial interest, I quit paying attention to the Softrock. As the years trickled by, the Softrock project kept moving. Lots of projects, mods, versions, and changes.

Here in the present, I had an older Softrock v6.2 sitting on the ‘ToooDooo” batting lineup since around December. It had originally been built as a 9Mhz IF kit, to be used as a panadapter. It was a gift from W3DQ. When I saw the NorCal group had a run of kits available, I ordered a pair. Wish it had been three….

But….it seemed like a good point in time too examine the IF kit, with an eye on re-working it for one of the bands of interest. As it was built, it required only four changes to put it on 40m. The Softrock Lite II kits come with components for building any band from 160m-20m, so the needed crystal was available from one of the kits. The mods took only a few minutes. That got done first.

On a roll, it was time to sift through one of the kits to see what the build was going to take. One thing leads to another….build it! The smell of solder smoke was soon wafting about. The “most difficult” surface mount parts were the first on the plate. As it turns out, these are not the smallest of surface mount parts. An ordinary 15w RatShack iron with a fine tip was sufficient for the task. The difficult part turned ot to be simply identifying the other parts. The numbers on the capacitors were difficult to read, and the color bands on the resistors all look like brown.

Lots of light and magnification? Better, but still some confusion. Most of the issue is progressive myopia, but I had not realized that color-blindness might also be progressive. Not so Fast! In order to get a second opinion, NumberTwoSon took a second look. Even with his 17 year old eyes and 20/13 vision, he also had difficulty.  So, after rolling out the ToolTimeTim’s XL 2550Super’scope, the parts were sorted.

After sorting, building was trivial.

Ran first skimmer test on both units on night of May 10th. Its interesting to see the spots a local skimmer finds versus thoses several hundred miles away. A whole project in itself….

By w4kaz, created on 2012.05.03 at 12:26:02 | last changed on 2012.05.03 at 12:45:01 | After a lot of procrastination, the dormant Softrock v6.2 project became timely. The job was to convert a Softrock v6.2 from its intended IF usage(IF 9.001?) to something a wee more interesting fer the KazShack main op, namely a 40m Softrock v6.2. The WB5RVZ pages are the place to go for build information. A fabulous job of documentation on the many SR permutations.

Turns out, the conversion was fairly simple. As built, there were only 2 component changes, add the RX enable jumper, and add a wire for the second “ring” line output. Oh….also change the crystal. A few resistance and then voltage checks. Use the K2 as frequency meter to check the crystal oscillator frequency, and its F/4 from the divider. (28.220 and 7.055+/-).

Fired off “Rocky”, VE3NEA’s SDR program. Putz around with the settings for Rocky and the sound card….Success! Sweet.

Now the question…….What the heck is this transient!!???!!

So…..the project is not quite complete. There are two full ready to build kits waiting on the sidelines (hat tip to AE5X for noting the availability). Still need to find a suitable enclosure. It also seems like inserting isolation transformers in the line-outs will be worth the time, and maybe the cost. A search on the radio shack site comes up empty for their audio iso xfmr. Mouser or Digikey.

Job one is a nice shielded enclosure, although there are lots of warnings about being wary of creating ground loops. Probably put an isolation transformer and front end protector on the inputs. Separate power source for the SR, and isolation transformer on the lineouts(insulated) to the sound card. Perhaps extra bypass caps on the power supply.

After that is done, maybe the transients will be reduced or eliminated.

Running Rocky on a dual core Pentium D causes the CPU to sometimes spike as high as 7%. Moving the mouse causes more CPU stress than the SDR software causes. Interesting.

Gonna be a lot of fun with this toy. 🙂

Many thanks to W3DQ for the original project package.

By w4kaz, created on 2012.02.25 at 20:16:52 | last changed on 2021.07.01 at 08:59:23 | Saga of transitioning to K2AV’s FCP(folded counterpoise)

(Updated 03/13/2021 de w4kaz, add/edit links and link to newer K2AV FCP page)Â Â NOTE: Please use this K2AV link for most current construction info

TopBand? Wazzat?

A saga of switching from raised radials to a version of the K2AV FCP for a 160m inverted-L.

The whole idea of operating on 160m started as curiosity. Before 2005 I had never operated on 160m. Ever. I had listened some, but never keyed the transmitter other than to experiment with arcing capacitors and high levels of SWR. But it generally seemed like it would be fun, so give it a try to find out, right?

After looking at a couple of locations in the yard, it seemed like there just wasn’t enough room to !easily! pull up an inverted-Vee, or other crooked dipole of such unusually large size. Tall trees out-the-wazooo in the yard, but spaced closely, so it is difficult for long pulls. There is an emphasis on easy because it is an important consideration. Any antenna that is a pain in the ass to maintain is more likely to be out of service at any given moment at the KazShack qth.

Where O where does a 160m antenna fit?

There is a great spot for a vertical rise of about 70 feet so that seemed to be the ticket. But verticals have their own downside. Radials – bleh!…Ick!…Ptui! But any antenna is better than no antenna at all, so that’s where we get sucked into 160m madness.

The first preference was a top loaded “T” but the useful supports are not arranged in a good pattern for that choice. There was just no way to stretch out the top-hat of the T.

The supports are arranged in such a way that an inverted-L is the logical choice. So a slightly long inverted L was the winner since it 1) fit into the yard where the trees line up, and 2) lends itself to capacitive matching if made slightly long. The result was an inv-L with the vertical section that goes up 70′, then across 40′, and across again in a different direction for another 50′. Approximately 155′(47m) of wire total length.

That leaves the radials. Buried radials just were not going to happen. Far too many tree roots and stone in the back yard, and no grass at all. What then is the nascent TopBander to do?

The Early years

The first Inv-L install circa 2005 had four elevated radials of equal length, about 37′ each. All were tied together and loaded via a coil at the base of the antenna. No chokes, and no decent matching network.  In this incarnation, antenna performance was poor. Even loud stations were difficult to work. Heard no DX. No surprises there.

The first “improvement” circa 2007 was to add 12 random length radials, a 1.5:1 step down unun(W2FMI design), and a coaxial choke wound from about 70′ of rg-58 wound on a PVC garden pot. The performance improvement, while not quantifiable was immediately noticeable. Stations became easier to work on a single call, and I was now able to detect the whispers of DX stations. A new K9AY for RX was also added to the mix just before these changes to the TX antenna. It also appeared that the improved TX antenna was now hearing most of what could be heard on the K9AY, although the K9Ay has a much lower noise floor and is usually much easier on the ears.

The Intermediate

Radials were added incrementally from 2007 through mid 2010 until there was a total of about 30. The original four 37 footers were the longest, and there were another four that were approximately 27 feet long. Everything else was a mish-mash of random lengths, added in pairs to the available trees in the area. Somewhere along the line(2008) I also added the capacitors required to get a good match at the base of the antenna, and have a nice low SWR both at the antenna base and at the shack-end of the feed line. And the nice narrow SWR bandwidth that accompanies such.

Performance of the final well-matched radial version of 2010 seemed to be quite good in comparison to the earliest version. In 2009 and 2010 it was possible to run stations(low power) in the 160m contests, and Q’s were made more often with the western US, as well as a handful of DX stations.

Before any other changes were made, I took some signal strength measurements in late 2011 using the K2 as field-strength meter, with the FT-920 as transmitter. The test configuration was 1) transmit full power from the FT-920 on the TX antenna at its lowest SWR point, 2)RX on the K2, using a dummy load at the end of a 7 foot jumper cable. dummy load hanging off edge of desk. K2 attenuator on, rf gain at max.

Using that configuration:

- 100w into the transmit antenna produces S-5 on K2 S-meter

- 100w into separate dummy load produces audible S-zero on K2 S-meter

As poor as it is, that reading is the best actual measurement available, from what in my opinion was the best of the radial configurations. Taken in early December 2011.

Decision Time

In 2009-2010, K2AV began discussing an idea he had for solving the small-lot-on-160m problem. Based on his modeling and studies of ground losses, he reasoned that a single counterpoise might be a solution that would work for space limited locations. He determined that a counterpoise that was 5/16th wavelengths might show useful current cancellations if it were strategically folded, to help with the problem of ground losses. So evolved the “5/16th wave folded counterpoise”, now being generally referred to as “516 FCP” or just as “an FCP” . The idea seemed to have a lot of merit, but being a serial procrastinator it took some time for me to get off my hindquarters and make the changes to try it out.

In early 2011, K2AV gave me one of his isolation transformers, as well as an inductor. Their implementations of the FCP at K2AV’s and W0UCE’s qth required additional inductance for matching(hence the inductor). They also discovered that the isolation transformer was a necessity to obtain good field strength results. The transformer design is beefy enough to handle their high power operations.  The design of the FCP has gone through some evolutions/refinements, and the design K2Av is recommending was originally field tested at his own qth in the 2011 CQ160m CW contest with low power, and with excellent results.

K2AV style FCP System Installed

My own original intent was to install his isolation transformer into my original system and transition to the FCP. Curiosity compels me to wonder what sort of improvement the isolation transformer might have provided on its own in the old system. That test never happened, but it is really just a matter of curiosity. It would still be good to know if the transformer would have made an improvement in signal with the radial jumble. I expect the choking on the radial system was less than ideal, far less than what was necessary, and the system probably was subject to higher losses because of that. That transition never happened, so I missed having the new system ready for ARRL DX. Impatience won out when an opportunity to do the work came up.

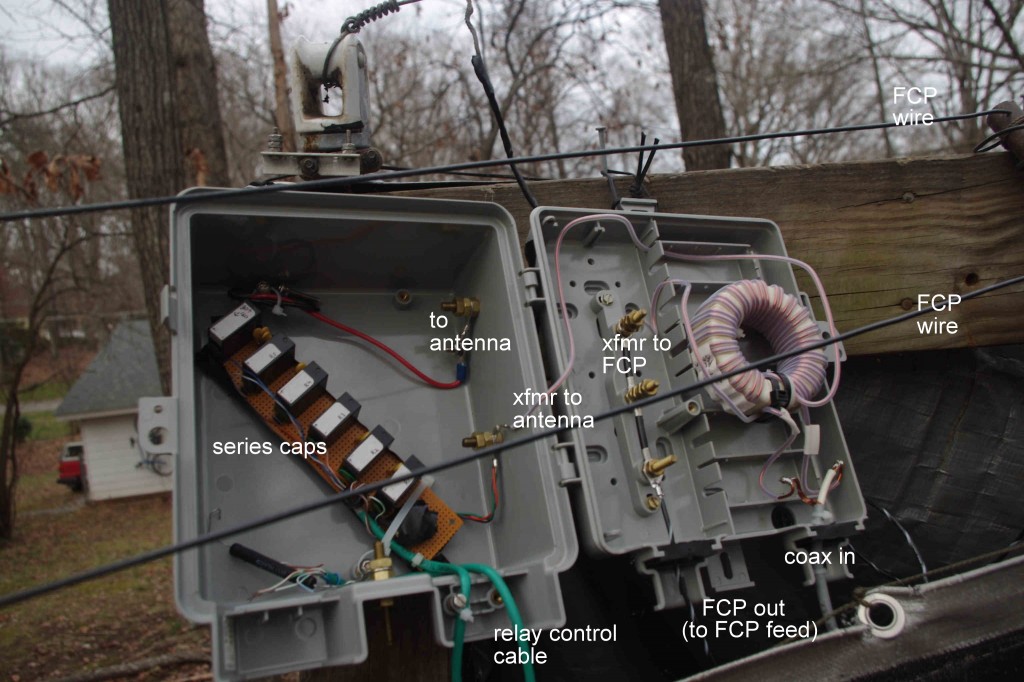

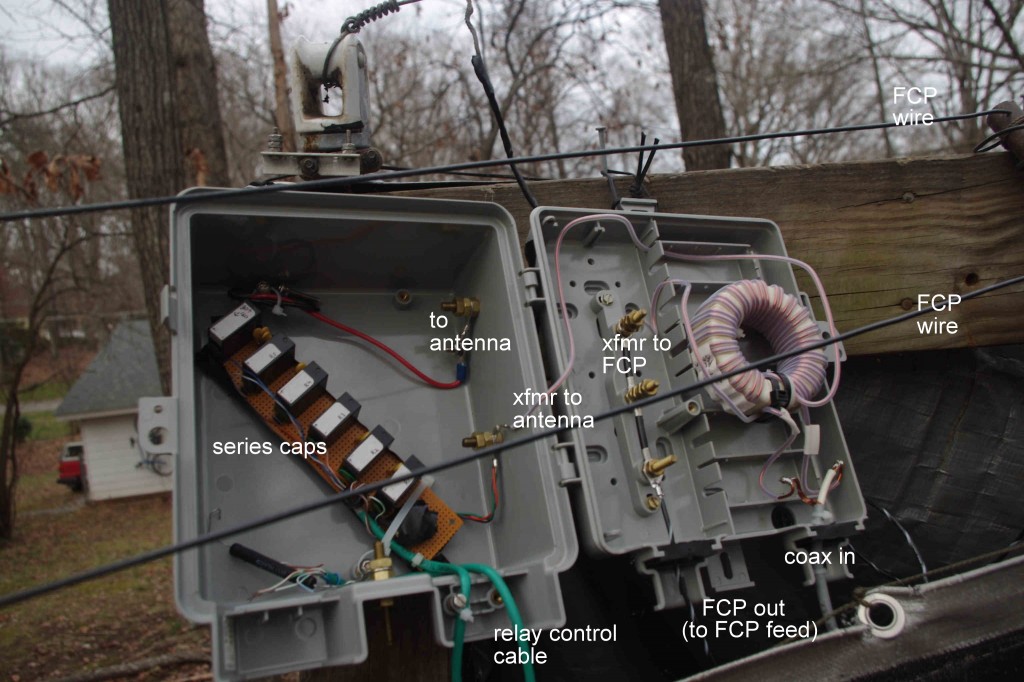

In the week after ARRL DX, the radials/coil were removed and K2AV’s folded counterpoise and isolation transformer were added to the antenna. [NEW link: K2AV FCP home page] A new junction box was built to house the isolation transformer and matching network. K2AV came by with his analyzer, and we spent a morning giving the system a look-see. As it turns out, the same value of matching capacitors were suitable for use without modification, and the inductor was not required because my inv-L is long. Matching the system was as simple as adding capacitance until a match was found. A large value air variable could be used to find the required match in less than five minutes, then replaced with capacitors suitable for handling the currents.

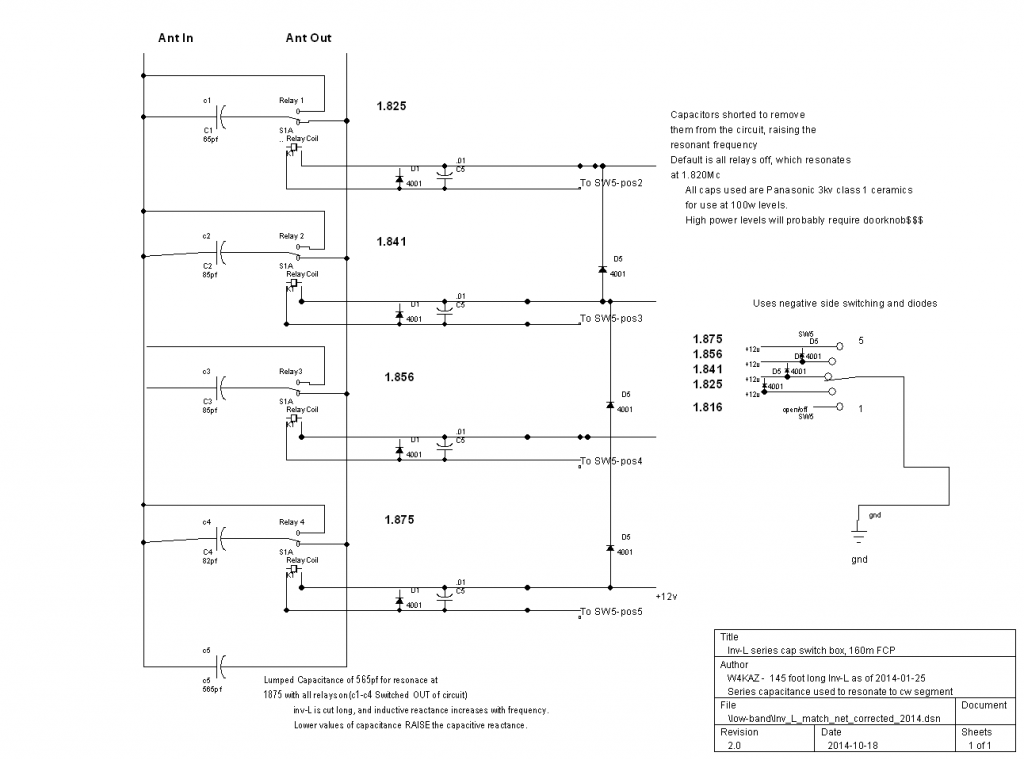

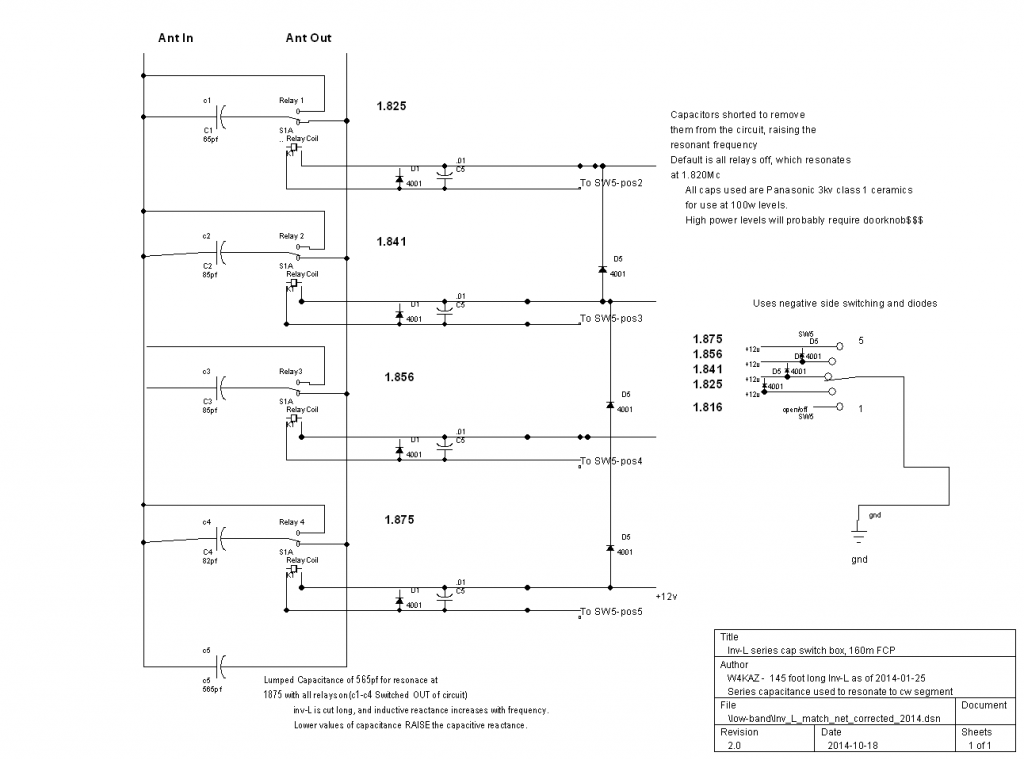

My own matching network is a group of HV ceramic caps in parallel[Obsolete, probably unavailable, 2016/09/25]. These are mounted on a board that allows switching some of the capacitance out to move the resonance up the band. The switch board will also allow switching to a different vertical element, but that feature won’t be useful without also switching the FCP. The FCP is a mono-band solution.

Schematic for W4KAZ 160m inverted L with K2AV FCP  Picture of W4KAZ 160m matching network and transformer junction box in use with 155 foot long inverted L and K2AV FCP The Present….So, What of it?

The system now up is the same/original inverted-l vertical section with the K2AV folded counterpoise and isolation transformer in place of the prior elevated radial jumble. What happened?

Using the K2 as field strength meter again, and using the exact same conditions as described above(sense antenna dummy load hanging from desk on 7 foot jumper):

- 20w into the antenna from FT-920 now registers S5 on K2 S-meter

- 40w into the antenna from FT-920 now registers S5 plus one bar on K2 S-meter

- 60w into the antenna from FT-920 now registers S5 plus two bars K2 S-meter

- 100w into the antenna from FT-920 now registers S9 (S5 plus three bars)

- 100w into separate dummy load produces audible S-zero on K2

The S-meter on this K2 is not calibrated in real world db, but even without knowing exact values the signal is obviously stronger than it was with the previous TX antenna system. Yes, that’s in the near field, but still it is encouraging.

The first field test was during 2011 Stew Perry. Anecdotally, I was very happy with antenna performance. It really seemed like I was louder, and it seemed I got fewer requests for fills. But the time for a full effort wasn’t there, so there is just a limited amount of data. Not too shabby for just three hours of operating.

A better sample was taken during the 2012 CQ 160m CW. (And here.) A total of 20 hours was operated. Terrible propagation conditions.  The first 6 or so hours were very good compared to previous 160m contests. 20 total hours of operation produced 593 QSO’s. Even with terrible conditions, I was able to work a couple of EU stations. Low Power. Not as good as K2AV in 2011, but one hell of a lot better than I anticipated, especially in poor conditions. K2AV is also a much better CW op, so I doubt I’ll ever be able to hit that 925 Q milestone.

So I’m pretty happy with the current system incorporating both the FCP and isolation transformer. Many thanks to K2AV!

W4KAZ Construction Variance Notes

In implementing the FCP design at the KazShack, I made a few variances from the recommendations.

The FCP itself is constructed of stranded 14ga hardware store THHN. I like the flexibility of the wire, the sturdy insulation, and most important, I have several rolls of it already bought and paid for.

The FCP insulators were cut from an unused piece of PVC electrical conduit. That was also what happened to be at hand in the form of spreaders from an experiment with hex-beams. From the length of PVC available for the job, I cut 16 spacers of 6 inches length(~150mm). Each was drilled through three times, a hole in the center, and one about .5 inches from each end. On the leg with two wires, the spacing is about 5 inches(125mm), while on the leg with three conductors the spacing is only ~2.5 inches(~60mm). The holes are intentionally mis-aligned or drilled at offset angles.   That allows the wire itself to place tension on the spreader to keep the spreaders in place. This method makes it easy to do with an ordinary hand drill – being crooked is an advantage. :)  The mis-alignment alone is not enough to keep the spreaders from sliding, so they are also wrapped with vinyl cable ties as needed. The distance between each spacer works out to about 4 feet(~1.3m). Vinyl cable ties are also used as spacers at the midpoint between each PVC spacer.

Measuring and threading the wire was the most time consuming part of the FCP construction. Because all of the separators are of equal size and drilled the same the side of the FCP with three conductors is more closely spaced than the side with two. This made mechanical construction very easy, the FCP is taut and sturdy, and does not seem to have any adverse effects on basic function.

The transformer and matching network is installed in a nice hamfest/surplus telco box, about 8x8x4. This is a nice weather tight enclosure. The transformer is exact to K2AV specs(by definition – it was wound by K2AV his-self!). The matching network of switched parallel caps is scavenged from the old weather enclosure(a sealed PVC pipe) and re-used in the new junction box. These components fit well enough, but there would not have been space to house the additional toroidal inductor had it been needed.

Besides the apparent signal improvements over the rejected-random-raised-radial-rambling-razzledazzle, the FCP itself has other very practical mechanical merits and advantages over raised radials.

- The folded counterpoise is simple to build.

- The FCP is relatively small, 32′ per side(64′ total length)

- The FCP is a LOT easier to deploy than 30 elevated radials, or burying a dense radial mat

- The FCP lends itself to following contours, and models well when the FCP is not perfectly straight

- The FCP will require a lot less maintenance. The odds of falling branches breaking the FCP here at the home QTH are lower by a factor of 15. (2 legs of FCP vs 30+ radials in 30+ directions, all below branch shedding trees)

- all of the above….. !! yipeee!!

Bottom Line…..

But Kaz, is it equivalent to a full size vertical with a dense mat of radials? Probably not, but there is absolutely zero chance that sort of system can ever be installed at this QTH, so the point is moot.

Do I care? Nope, it “works”, and it “works” better than it’s predecessor 160m antenna systems AT THIS QTH. Very possible/likely that improvement is just a testimony to the poor performance of the prior system. But better is “better”.

Is it snake oil? Probably not, at least not according to the CW skimmer robots, the results K2AV has had with his system, and more important, my own field testing during the CQ160m contest. W8JI has done some comparisons of models. But since they are comparisons to antennas that will not be practical at W4KAZ location, it is academic info. For use here it is about the footprint and 80 foot radials are simply not practical HERE.

2021-03-14 Notation….Nothing Changed

At this point, my only regret is an academic point – not having run the test of inserting the isolation transformer into the old system with the radial-jumble.  The sharp tuning of most 160m antennas suggests that common mode currents will often be a problem as one tunes away from the antenna’s resonance and the reactance increases.   How much benefit is gained from either the isolation transformer or the FCP individually is unknown(to me), but still of both practical and academic interest. I’d really like to know if the old system would have been improved with the isolation transformer installed. Still of interest, but not enough for me to spend time hanging the radials back up again! ;)  Together, the FCP and transformer seem to do a damn fine job here. Certainly the best system that has been active in this location.

What next? FCP phased verticals…..FCP foursquares…..FCP parasitic arrays….. MANY possibilities - if only I had the room to do it.

References:

The K2AV reference page should be used for the most current work by K2AV.

* * *USE DATA FROM HERE:–>https://k2av.com/ * * *

Historical references, related opinions, original subject matter posts, and a few older message threads on the TopBand mail list on pertinent topics:

- Original K2AV NCJ article “The FCP: A 160 Meter Counterpoise for a Postage-Stamp Lot “

- W0UCE’s accumulation of information on K2AV’s 160m ideas, including the FCP

- Photos from W4KAZ FCP install

- Older K2AV discussion of the FCP

- K9YC: “Working 160M From a Small Lot (and Larger Ones Too)”, http://audiosystemsgroup.com/160MPacificon.pdf

- W8JI on FCP, a comparison to antennas that I cannot have.

- Rolling your own FCP isolation transformer, IMPORTANT

- Topband: Where to place a preamp? Switching Beverages?

- Topband: K2AV 160m Folded Counterpoise (FCP), parts and winding for isolation transformer

- Re: Topband: K2AV 160m Folded Counterpoise Antenna (wire suggestions)

- Re: Topband: T-200 vs. T-300

- 2012-05-31, VO1HP FCP install

- Balun Designs commercially available FCP transformer

Other links:

- W1UJ : http://w1uj.net/FCP/

- KY6R : https://ky6r.wordpress.com/2015/04/27/160m-fcp/

- IV3PRK(FCP @ HC1PF) : http://www.iv3prk.it/hc1pf-tx-antenna.htm

- DL0WH : http://dl0wh.de/80m-vertikal-mit-gefaltetem-gegengewicht-nach-k2av/

- DM9EE: http://www.dm9ee.de/FCP_info.html, and http://dm9ee.de/fcp-radials/

- W8TN : https://w8tn.blogspot.com/2012/07/building-k2av-fcp-160-m-antenna.html

- WB5NHL : http://oldcyberdude.com/sample-page/antennas/160m-folded-counterpoise?

- LA9XGA FCP : https://la9xga.com/?cat=54

- M0KWR: http://m0kwr.com/Antennas.html

- AC2RL article in RDXA Fall 2018 (see page 16)

- LA9XGA install: https://la9xga.com/?p=610

- VA3KGS & VA3AC slides on FCP in array

- AC9EZ(pg3 in ACARTS newsletter)

- *

- *

By w4kaz, created on 2012.01.27 at 18:05:45 | last changed on 2012.01.27 at 18:05:45 | Getting the last minute woolgathering in before the contest begins.

Made a last-minute antenna mod to the Inv-L with K2AV FCP. The antenna matching network has been ready for switching out matching capacitors for over a year. The missing piece has been a control box and control cable to the feedpoint. After a bit of consideration of solving this issue before the contest, the brain caught up and realized an interim solution was already in place.

When the Sixpak was added to the antenna system a couple of years back, the existing seven position switch was pressed into ‘temporary’ service as an A/B switch for a pair of 40m dipoles. But they occupy positions 1 & 2 on the switch.

So why not use the other switch positions to serve double duty? The switch is about ten feet from the base of the 160m antenna, so its a short run of control cable versus the 80 run needed back to the shack.

So as a quick and dirty solution, I hacked together a plug to mate to the switch control line. Just plug the 160m switch into the control cable for the seven position switch.

Presto-change-o. Now I can move the best match on 160m from 1820 up to 1845. Sufficient for a CW contest, although 1855 would be ideal. More tweaking needed, but better.

Goals for the weekend are more or less to lay down a good set of spots into the Reverse Beacon Network. No real QSO goals. Try to maximize time spent running, and try to do it over two nights.

C U LÂ Â de w4kaz

By w4kaz, created on 2012.01.20 at 06:48:47 | last changed on 2012.01.19 at 12:11:53 | One of the things that kept me away from the keyboard was a woodwork project idea.

Several years back, I saw a design for a compact kitchen/breakfast table. The tabletop folded over to convert the table into a bench. The basic idea was used to build two outdoor tables of similar design. They are very functional, but a bit heavy. One is in daily use as a catch all work table. The other slightly larger table is on the backyard patio and is used with the tabletop grill.

The eldest son moved to an off campus apartment which has a large deck. It seemed like a good place for a similar table. So it was time to pencil out a new design that I could put together for an updated “new and improved” version. Several years of use had made some of the shortcomings of the original tables obvious. The “new” ideas are that: 1) it needed to fit into the car for transport, and 2) should be made of lighter weight materials to generally make it easier to move around. This is what popped out…….

First attempt at picnic table bench Not a terribly good photo, but there are a few more coming.

The table has four components: 2 sides, the top, and the bench. The sides are simply bolted to the bench with 1/4 inch carriage bolts, while the top rests on top of the top arms of the side pieces. The top is simply pinned into place using 1/4 inch J bolts. The top itself is formed from boards attached to ribs with deck screws, all countersunk from below keeping the tabletop unblemished.  The table top hinges over on the rear pair of J-bolts to become the backrest for the bench. Pictures are better….

Picnic table with top folded back as bench. The materials used are all pressure treated pine lumber. To give the surfaces a bit of a protective finish, the table top got four or five coats of good old-fashioned pure tung oil, which incidentally has become difficult to find. I like tung oil – it is more resistant to mold and mildew, so is better for an outdoor application than boiled linseed oil, and I expect it to hold up in the mountain UV sunlight a lot better than a polyurethane. After its dried, tung oil is also resistant to alcohol and related solvents. Good stuff. I suppose it has fallen from favor because of the rise in popularity of the polyurethanes, and the substitution of the less expensive boiled linseed oil finishes. It was also a bit of an experiment, as none of the other normal finishes are worth a flying-*#%^ on pressure treated lumber, whereas tung oil does a better job on this material and is non-toxic, unlike oils designed for treating pressure treated decks.

So the table top and bench have a nice hand buffed tung oil finish. Its difficult to tell in these photos, but that experiment was proven to be effective.

The back of the bench As it turns out, the selection of pressure treated that happened to be in the bin at the big-box-lumber-retailer included several nice heart-pine crosscuts, which had nice colored grain detail. The coloration was enhanced by the oil finish. It really looks a lot better than I expected. Almost kept this one and made a second table for NumberOneSon. 😮

side view of bench attachment to side arms |

Inside/underside view of bench attachment to side arm |

The problem areas in the design relate to the hinging of the table top and its use as a seat back. The sides of the table are made from deck ballusters. I’ve found that these are generally cut from knot free sections of clear even-grained wood, and are quite strong. Also relatively inexpensive. So the side sections are held together with deck screws and waterproof polyurethane exterior construction adhesive. The top rail may not be strong enough for the hinge, and may eventually need a re-inforcement of steel or aluminum added.

Also, the original benches had wider sides, which served to “stop” the bench top fold over at just over 90 degree seat back angle. Solving that problem on this new bench did not occur to me until it became clear the sides here will allow the top to hinge over well past a comfortable seat-back angle. So the kludge to remedy that design flaw was a simple chunk of balluster attached at angle on the inside of the sides. It helps add rigidity to the sides as well as acting as a bumper for the table top when hinged over as a seat.

Side view of table with top hinged over for use as bench Just right for soaking up a bit of mountain sunshine – and hopefully the moonshine won’t eat away the finish.

By w4kaz, created on 2010.09.24 at 08:49:18 | last changed on 2010.09.13 at 08:49:28 | Sometimes common sense is everything but common. Just never can find the right adapters when hooking everything back together.

Case in point: It is a lot easier to use 1/8th(3.5mm) stereo plugs, and use an adapter to go up in size to 1/4 inch.  Going from large to small just adds stress to the connections. The smaller size is also becoming the more commonly used jack on gear as the gear itself becomes smaller. Soldering the teensy connectors is more of a PITA, but such is life.

Just as soon chop all of the paddle and keyer plugs now – almost all of the shack radio gear has 1/8th jacks now. But the peripherals seem to all still have 1/4 plugs.

Another fun fact: It’s easier to use all stereo connectors than a mix of stereo and mono. A stereo plug can be wired tip and shell for mono usage, but a mono plug is worthless when you need stereo.  So to hell with mono 1/8th and 1/4 audio connectors. They are banished forevermore from the KazShack.

Soldering Tip: When soldering RCA, 1/8th or 1/4 plugs, it is worthwhile heat sinking the connector, especially with low-quality connectors. The easiest way is to just plug them into a jack. That seems to provide enough sinking, unless you really try to cook them. This seems to really be helpful with RCA connections, where the center pin will sometimes drift if the connector is overheated. Using an RCA barrel as heat sink allows a melted connection to re-solidify correctly aligned. Good to go, unless it shorted when overcooked.

By w4kaz, created on 2010.09.13 at 08:22:04 | last changed on 2010.09.13 at 08:22:04 | I built the Idiom Press cmos-IV Logikeyer a couple of years back, and it is the best keyer I have owned. Easy to build kit too. N4YDU has recently added one to his collection too. A great external keyer, and good for field operations.

Idiom Press has two new products that look very interesting, a stand-alone voice keyer, and an outboard RF speech processor. The voice keyer looks like it is exactly what I wanted – perfect for Field Day or the IOTA expedition. Also useful if routing audio from the computer is an issue.

The speech processor is yet not priced on the web-site. That’s a good thing, since I’m not ready to BUY yet. Both products would make a difference for low power operating/field day.

Recent station derangements have re-introduce an RFI issue onto the K2. This is a bit of a puzzle, but I expect to find a case of “ID-ten-T” is involved. Just not yet sure where. Looking at the setup fresh may help, but I see one link in the chain I want to meddle with right away. I’d eventually like the audio transformers in the SO2R switch box at each of the radio lines. That would keep all three audio devices(computer, radio1, radio 2) isolated – currently not the case.

A mini experiment is in the works there, by isolating only the computer audio before it enters the SO2R switch box. I expect a transformer at that point in the stream to have no effect on the problem, but if it works I may make no other changes.

|

|